CATEGORIES

- VENEER PRODUCTION

- log handing sorting and cutting

- log debarking and rounding machi

- veneer peeling

- veneer clipper

- veneer drying

- veneer composing

- veneer stacking and sorting

- veneer scarf-jointing

- veneer patching

- other veneer machines

- PLYWOOD PRODUCTION

- plywood lay-up

- plywood pressing

- panel repairing puttying

- panel trimming

- panel sanding

- panel overlaying

- panel edge painting

- panel grading and sorting

- other plywood machine

LATEST NEWS

- what's dyed veneer

- Several common veneer quality problems

- plywood putty line

- how to use chinese spindle-less veneer

- plywood sanding machine using

- the principle of the veneer peeling ma

CONTACT US

- ADD: A4-3-101 HUIGU ROYAL SANGUANMIAO JIUQU HEDONG DISTRICT LINYI CITY

- TEL: 0086-186 6967 1318(WHATSAPP)

- FAX: 0086-539-8390323

- E-mail: info@veneermachine.com

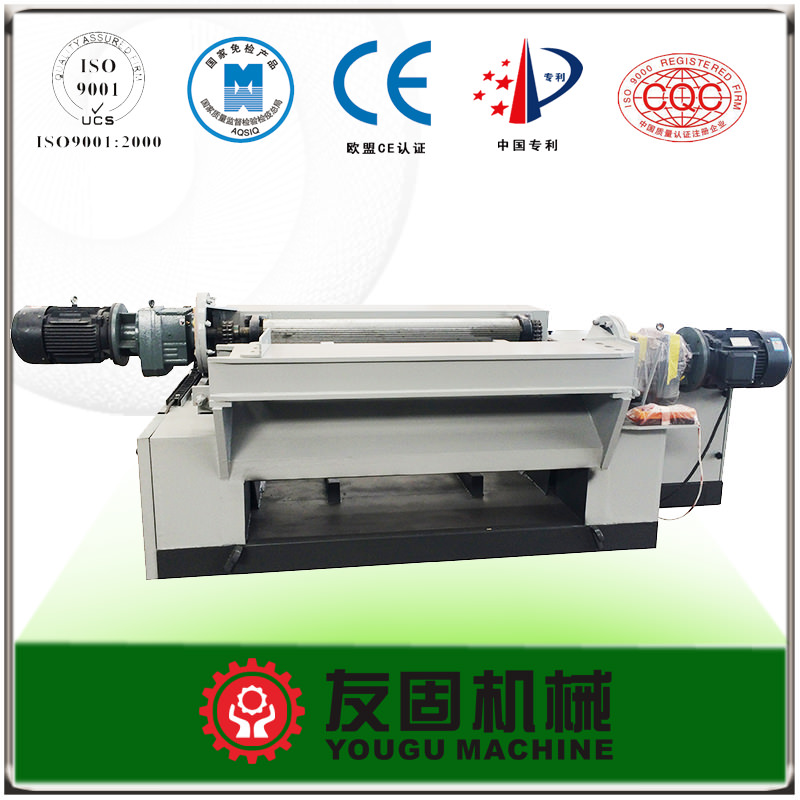

4 feet heavy duty log debarking machine

- 4 feet heavy duty log debarking machine

- log rounding machine

- strong frame and strong power

- Product description: heavy duty type big diameter log debarker log debarking machine plywood making machine simple plywood making machine line

- Product description: Log debarker is used for rounding log and removing the bark before peeling. And it is suitable for the eucalyptus, pine, cotton wood and other trees. Before peeling, it removes the log’s skin and make

PRODUCT INTRODUCTION

|

Parameter |

Value |

Notes |

|

Length of the Roller(mm) |

1500 |

|

|

Power of Double Roller(kw) |

11kw*2 |

AC induction motor |

|

Double Roller Reducer |

Gear Reducer X 2 |

350 |

|

Double roller diameter |

200mm |

|

|

Power of Single Roller(kw) |

11kw |

AC induction motor |

|

Single Roller Reducer |

Gear Reducer X 1 |

350 |

|

Single roller diameter |

150mm |

|

|

Power of Oil Pump(kw) |

7.5kw |

AC induction motor |

|

Total Power(Kw) |

40.5kw |

|

|

Max opening |

500mm |

|

|

Min diameter of logs |

90mm |

|

|

Size(mm) |

3700*2200*1650(L*W*H) |

|

|

Weight(kg) |

6500 |

|

Log debarker is used for rounding log and removing the bark before peeling. And it is suitable for the eucalyptus, pine, cotton wood and other trees. Before peeling, it removes the log’s skin and makes wood straight. Chrome plated rollers are more wear-resitant. Grooves along the roller surface make it difficult for bark to get stuck around the rollers. Hydraulic driven feed mechanism can quickly and efficiently put Log in and remove bark and make the wood round.

Well-designed with quality materials and precise manufacturing, each part ensures the continuity of the quality work. One set debarker can supply 2 sets peeling machine. A front and back feed keeps the logs moving in and out of the debarker efficiently anda large oil pump keeps the feeds well-lubricated and working smoothly. It greatly saves the original manual peeling and rounding procedure, helping save 5-6 workers.-

New design gear type double roller,can save rounding log time.and the life of rollers longer.