CATEGORIES

- VENEER PRODUCTION

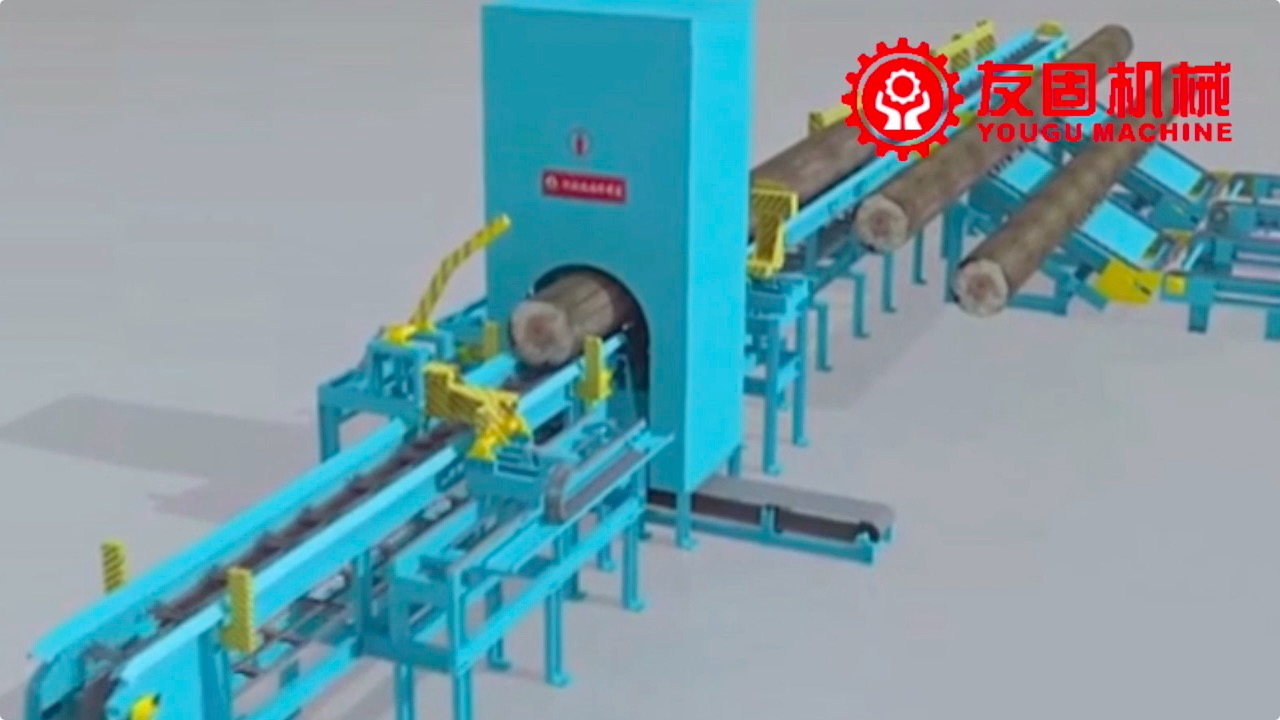

- log handing sorting and cutting

- log debarking and rounding machi

- veneer peeling

- veneer clipper

- veneer drying

- veneer composing

- veneer stacking and sorting

- veneer scarf-jointing

- veneer patching

- other veneer machines

- PLYWOOD PRODUCTION

- plywood lay-up

- plywood pressing

- panel repairing puttying

- panel trimming

- panel sanding

- panel overlaying

- panel edge painting

- panel grading and sorting

- other plywood machine

LATEST NEWS

- what's dyed veneer

- Several common veneer quality problems

- plywood putty line

- how to use chinese spindle-less veneer

- plywood sanding machine using

- the principle of the veneer peeling ma

CONTACT US

- ADD: A4-3-101 HUIGU ROYAL SANGUANMIAO JIUQU HEDONG DISTRICT LINYI CITY

- TEL: 0086-186 6967 1318(WHATSAPP)

- FAX: 0086-539-8390323

- E-mail: info@veneermachine.com

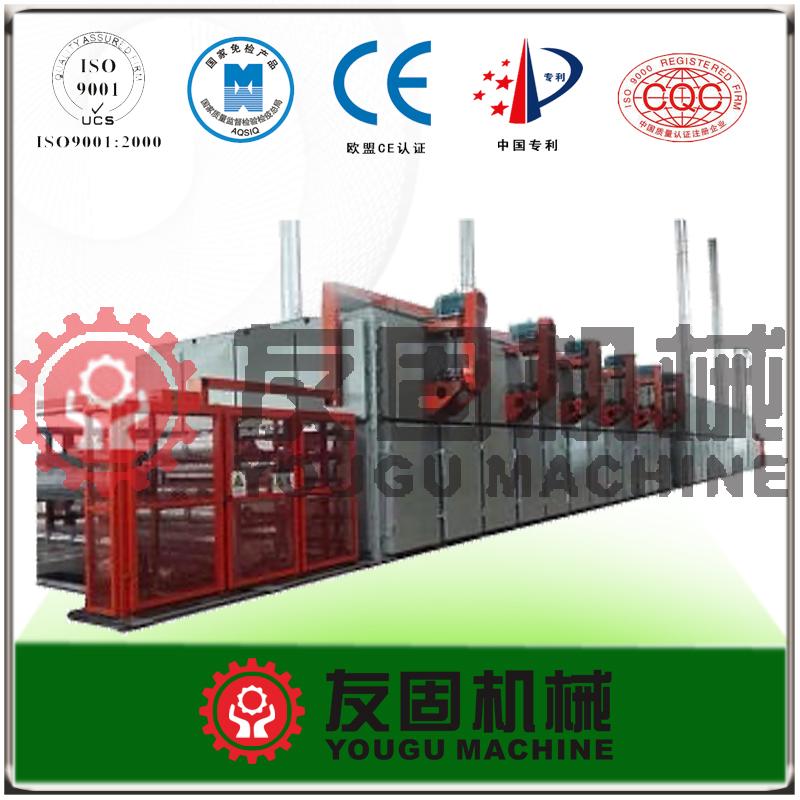

plywood face veneer dryer

- plywood face veneer dryer

- belt type

- high capacity

- can design and made by order

- Product description: plywood face veneer dryer Veneer drying is one of the most crucial phases of veneer production. The main objective of the drying process is to produce high-quality optimally dried veneer sheets with t

PRODUCT INTRODUCTION

plywood face veneer dryer Veneer drying is one of the most crucial phases of veneer production. The main objective of the drying process is to produce high-quality optimally dried veneer sheets with the highest possible efficiency. This is carried out by removing water from the sheet and decreasing moisture content to an optimized level by using hot and humid air inside a dryer.

|

NAME |

UNIT |

PARAMETER |

PARAMETER |

|

Working width |

MM |

2800/3000 |

3000 |

|

Layers |

|

2/3 |

4 |

|

Heating section |

MM |

11set/12set*2000mm |

14set*2000mm |

|

Cooling section |

MM |

1set*2000mm |

1set*2000mm |

|

Feeding area length |

MM |

2000/4000 |

1000 |

|

Collecting area length |

MM |

4000/5000 |

1000 |

|

Transmission motor total power |

KW |

7.5kw*2set/3set Frequncy control |

11kw*4set Frequency control |

|

Total power |

KW |

78.5/158.5 |

204 |

|

Heating blower motor |

KW |

5.5kw*11set/11kw*12set |

11kw*14set |

|

Cooling blower motor |

KW |

3kw/4kw*1set |

3kw*2set |

|

Transmission speed |

M/MIN |

1-30 |

0-30 |

|

Radiator size |

MM |

11set/12set*(L)2000*(W)400*(H)900/1500 |

14set*(L)2000*(W)400*(H)2000 |

|

Heating medium |

|

Steam or Conduction oil |

steam or conduction oil |

|

Drying temperature |

℃ |

130-180/160-190 |

160-190 |

|

Heat consumption |

KCAL/H |

800000kcal/小时 120万大卡/2700000kcal/小时 140万大卡 |

4400000kcal/小时 300—400万大卡 |

|

Veneer thickness |

MM |

1-4 |

0.2-4.0 |

|

Veneer Initial Water Content |

% |

20-30/60 |

60 |

|

Veneer Final Water content |

% |

4±2/10±2 |

10±2 |

|

Production Capacity |

M³/H |

1.5-2/2.5-3 |

3.4-4 |

|

Distance between rollers |

MM |

180 |

/ |

|

Diameter of rollers |

MM |

102 |

/ |

|

Quantity of rollers |

PC |

580/920 |

/ |

|

Machine Size |

MM |

(L)30000/35000*(W)4000/4200*(H)2800/3600 |

(L)50000*(W)4200*(H)4500 |

|

Machine Weight |

KG |

40000/60000 |

74000 |