CATEGORIES

- VENEER PRODUCTION

- log handing sorting and cutting

- log debarking and rounding machi

- veneer peeling

- veneer clipper

- veneer drying

- veneer composing

- veneer stacking and sorting

- veneer scarf-jointing

- veneer patching

- other veneer machines

- PLYWOOD PRODUCTION

- plywood lay-up

- plywood pressing

- panel repairing puttying

- panel trimming

- panel sanding

- panel overlaying

- panel edge painting

- panel grading and sorting

- other plywood machine

LATEST NEWS

- what's dyed veneer

- Several common veneer quality problems

- plywood putty line

- how to use chinese spindle-less veneer

- plywood sanding machine using

- the principle of the veneer peeling ma

CONTACT US

- ADD: A4-3-101 HUIGU ROYAL SANGUANMIAO JIUQU HEDONG DISTRICT LINYI CITY

- TEL: 0086-186 6967 1318(WHATSAPP)

- FAX: 0086-539-8390323

- E-mail: info@veneermachine.com

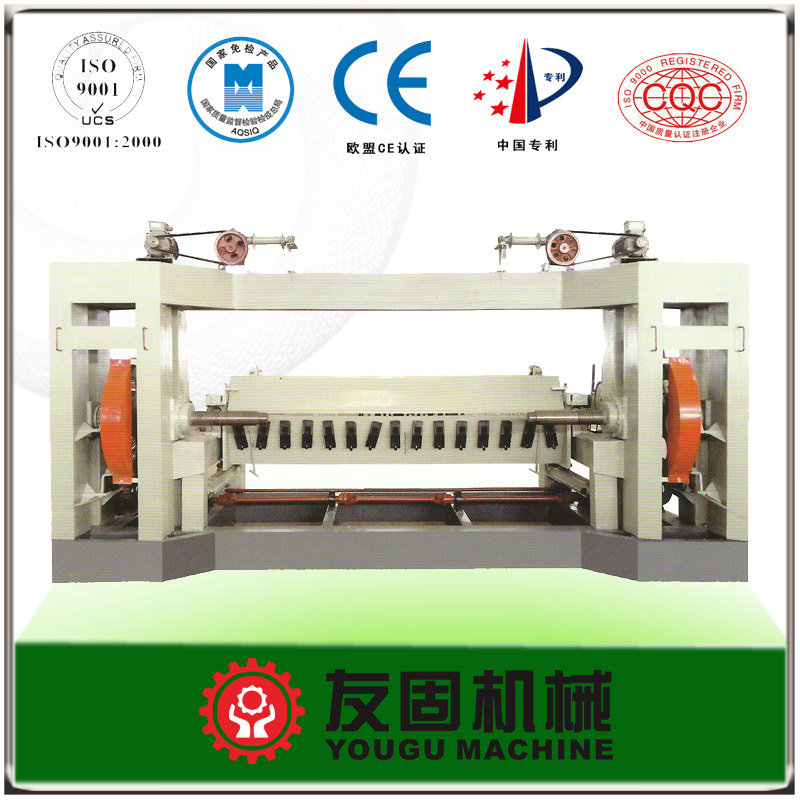

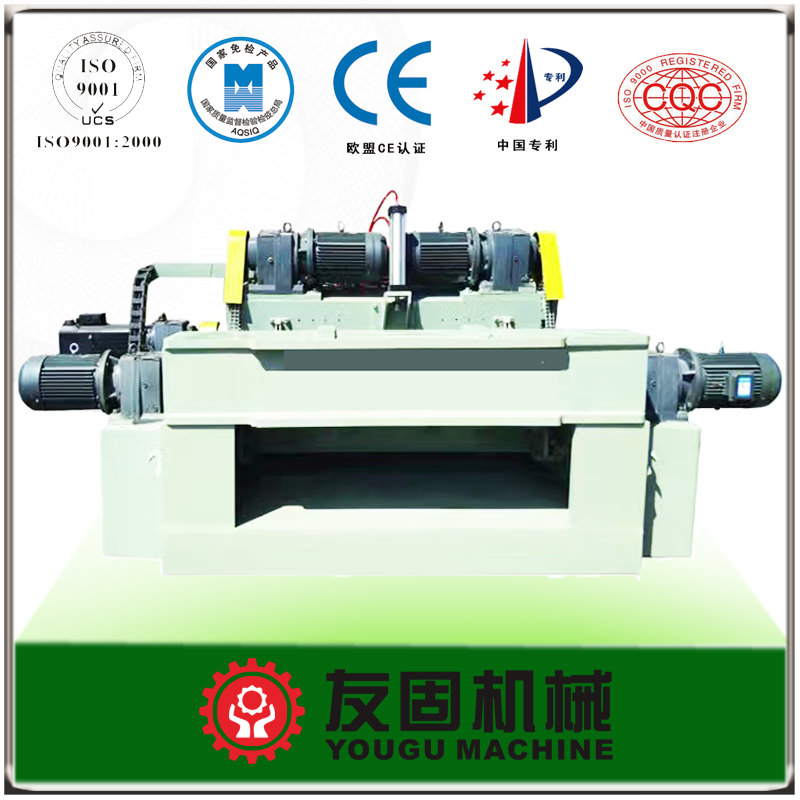

heavy duty veneer peeling lathe

- veneer peeling lathe

- heavy duty

- fast speed

- max 80m/min

- Product description: heavy duty veneer peeling lathe for core veneer making machine,veneer clipper machine

PRODUCT INTRODUCTION

4 feet heavy duty veneer peeling lathe

1. Highest speed of the veneer peeling machine in China. Peeling speed can be fast as 80m/min.

2. Save power for 30% - 50 %. Normally the running current only the 50% of the rated current.

3. Good quality of the veneer, smooth and evenness, thickness err plus and minus 0.05mm.

4. Stable the roller running speed, reduce the influence of the voltage fluctuate.

5. Automatic speed down when peeling end, reduce the shock of the machine, makes bearings and machine long durable.

6. Advanced control system and core technology.

7. Clipper integrated model, peeling and clipping at same time.

|

Parameter |

Value |

Notes |

|

Length of the Roller(mm) |

1500 |

|

|

Power of Double Roller(kw) |

7.5kw X 2 |

AC induction motor |

|

Power of Single Roller(kw) |

5.5kw X 2 |

AC induction motor |

|

Power of Screw Feed(kw) |

7.5kw |

AC Servo induction motor |

|

Power of Rotary Clipper(kw) |

1.5kw |

AC Servo induction motor |

|

Power of Rubber roller (kw) |

1.5kw |

AC induction motors |

|

Total Power(Kw) |

36.5kw |

|

|

Roller Reducer |

Helical Gear Reductor X 4 |

|

|

Screw Feed Reducer |

Helical Gear Reductor X 1 |

|

|

Clipper Reducer |

Helical Gear Reductor X 1 |

|

|

Rubber Roller Reducer |

Helical Gear Reductor X 1 |

|

|

Veneer output speed(m/min) |

30-80 m/min Adjustable |

|

|

Blade (mm) |

1500*180*16 |

|

|

Max opening |

500mm |

|

|

Minimum Log core |

28mm / 20mm |

Crossed Double Roller :20mm |

|

Thickness(mm) |

0.6 – 6.0 |

|

|

Clipper width(mm) |

>= 400 mm |

|

|

Control Unit |

Peeling Speed Adjust System Closed loop Servo control |

Beijing LEAD Technology |

|

Weight(kg) |

6500 |

|